Computer Software for Steel Professionals

Structural Material Manager Plate-Nesting Module

Structural Material Manager's optional Plate-Nesting Module finds the optimal cutting pattern of the job's plates out of the specified stock sizes. By running literally thousands of complex mathematical computations in a very short time frame, it eliminates the hours of time that are normally spent manually determining cutting patterns. The result of this processing is an actual pictorial layout of the pattern that results in the least wasted material.

You are able to specify up to 20 different stock plate sizes for each plate thickness and grade, i.e., 20 different sizes for the 1/4" Grade A36 plates, 20 different ones for the 1/2" Grade A588 plates, etc. For each stock size, a different "kerf" or cut-width value from 0" to 3" can be specified; the system leaves the specified amount of space between all adjacent items placed in the stock.

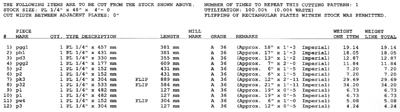

Rectangular items can be rotated 90 degrees within the stock if the user permits this. Permitting such rotations allows the system to analyze more combinations, so this will usually produce more accurate nests. The user usually permits rotations unless it is important to maintain a certain grain orientation. The word "FLIP" appears in the summary to call your attention to any plates that are turned sideways in the layout.

The sample below shows various metric plates nested into a 4'-0 square 1/4" stock plate. Canadian clients encounter such mixes of metric and imperial designations frequently. Also, U.S. clients sometimes work with foreign drawings that specify metric dimensions for items that are actually to be cut from standard Imperial steel sections. Of course, all plate dimensions can also be entered in feet and inches.

The Plate-Nesting Module prints a summary beneath each cutting pattern. Below is a thumbnail image of a sample summary; click to enlarge it to full size:

Some fabrication shops shear plates up to a certain thickness. If your shop does so, you can easily set thickness thresholds that tell Structural Material Manager which plate thickness should be sheared. Very different cutting diagrams are generated for sheared plates as opposed to those that are to be cut using a saw blade, water jet, flame, laser, plasma, etc. Click here for full details.