Computer Software for Steel Professionals

Structural Material Manager Software Videos

The User's Guide is the primary source of Structural Material Manager information. It is available at the program's setup screen before installation, in the Help menu after installation or online by clicking here. Sometimes, though, a picture really is worth a thousand words, and that is the purpose of the videos you'll find at this page. They are not meant to replace the User's Guide but, rather, to supplement it.

Installing and Activating the Fully-Functional Demo - Structural Material Manager offers a fully-functional software demo. It is available on physical media (USB Flash) or as an Internet download.

Overview of Some System Functions - This video broadly introduces several topics without getting bogged down in detailed information. It shows how material items are entered or - better yet - can be imported. Unorted, Sorted and Nested Reports are demonstrated here. Finally, the video shows how a Buy List of gross material requirements can be easily generated.

Finding Text at the Material List - The Material Entry Screen has a function that searches the material list for the specified text. Use this feature to find piece marks, item sizes, material grades, etc. anywhere in the entire list or just within the selected material lines.

Limiting Text Search to Exact Matches - Searching for text at the Material Entry Screen is enhanced by an "exact match" option. This prevents extraneous matches due to lines that merely contain the search string rather than having the precise text for which you are searching. In a general sense, this would mean that the word eight would not be an exact match for the word weight. More specifically relevant to the steel industry, the Exact Match option causes piece mark p32 to not be accidentally found as a match when mark p3 is the search text.

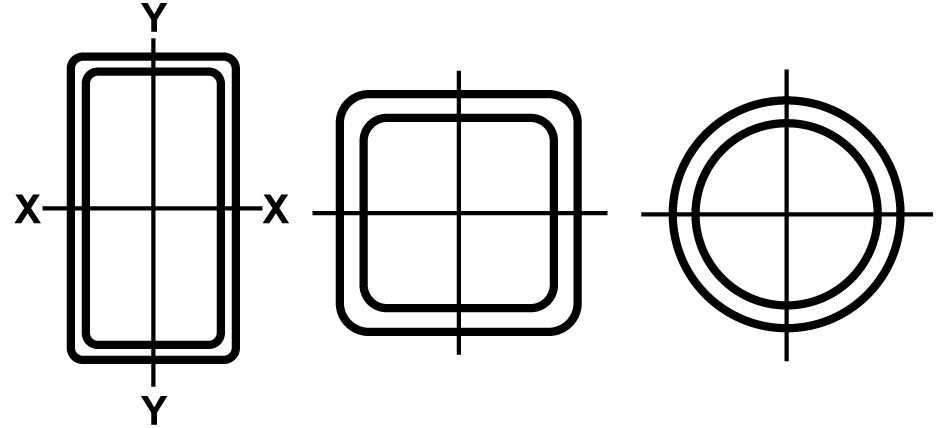

Plate-to-Bar and Bar-to-Plate Conversions - If you receive a bill of material only to find that many items that you'd prefer to specify as Bars are instead listed as Plates, don't fret. Simply allow Structural Material Manager to handle the conversion. Its Plate-to-Bar and Bar-to-Plate functions easily switch back and forth between the two designations.

Display Styles - Tired of the same-old-same-old when it comes to the look and feel of your Windows applications? Structural Material Manager provides over 50 custom display styles from which to choose. Some subtly freshen the Graphical User Interface (GUI) experience whereas others dramatically alter the appearance.

Multiple Selections - Microsoft Windows' concept of a multiple selection is very useful when entering Structural Material Manager bills of material.

Importing CAD Bills of Material - There is no need to re-type bills of material that already exist in a steel detailing system. Simply have that application export the material list to Structural Material Manager's External Data Interface format (or even the generalized KISS format), and Structural Material Manager can then import the items.

Importing Job Revisions - The External Data Interface has a feature that makes it aware of revisions during import. Imported lines are compared against existing ones so you can decide whether they should replace those existing items instead of being added to the material list.

Mass Replacement of a Field - Eliminate repetitive editing of items when the same change needs made multiple times. By first making a simple multiple selection, you can save time by instructing Structural Material Manager to mass-replace a field within that entire selection. Making changes to all occurrences of a certain piece mark or perhaps all items of the same material type is thus easy.

Automatically Repeating Edits to Items of the Same Piece Mark - Suppose you edit an item of a certain piece mark, and items of that same mark appear throughout the material list. It is not necessary to painstakingly change each material line. Once you change any one such item, the system pops up a dialog asking whether you'd like those same edits automatically made to all other items of that same piece mark.

Nesting Against Inventory - In additional to nesting against unlimited quantities of standard stock lengths, the Length-Nesting Module can access stocks from in-house inventory or your supplier's stock. A perpetual in-house inventory can be maintained since stocks used from in-house inventory can be automatically relieved. Useful remnants can also be automatically added back to inventory.

Creating Shipping Reports and Tickets - The Production-Control Module allows structural steel fabricators to produce shipping reports based on major piece marks. Reports include Shipping Lists, Master Shippers, Shipping Tickets, and more.

Printing Shipping Status Reports and Shortage Reports - Once a job has had Shipping Tickets stored in its Production-Control history, both Status Reports and Shortage Reports are available.

Sorting Shipping Ticket Piece Marks - The Build Shipping Ticket Dialog has a function that automatically sorts the major marks that will appear on the Shipping Ticket. Use this feature to quickly put the marks in alpha-numeric order without having to move them up and down in the list one by one.

Deleting a Shipping Ticket - When Shipping Tickets have been created for the purpose of mid-point shipping (a.k.a. interim ship-points) so loads can be sent for outsourced processing, it later is necessary to delete them. That releases those items from the job's Production-Control history so they are once again available for shipment on a new ticket to the job site.

Resizing Material Entry Screen Fields - The fields listed acroass the material entry screen can be widened, narrowed or even hidden completely based on your individual needs.

Exporting a List of Folders and Jobs - Create a .CSV file that lists each Structural Material Manager folder and every job contained therein. Opening that .CSV file in Excel provides great flexibility in alphanumerically sorting the list, searching for a certain job name, etc.

Automatic Backup of Jobs - The system automatically keeps a large number of backup versions of each job without any need for user action. A "Restore Automatic Backup" dialog provides easy recourse in the event that the job becomes corrupt, someone accidentally deletes it, etc.